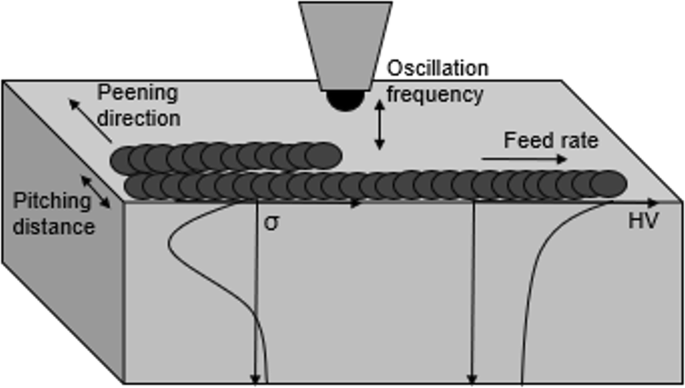

Effect of Overlap in Robotic Hammer Peening on the Surface Integrity of Alloy Steel 4142 | SpringerLink

Machines | Free Full-Text | Optimization of Hammer Peening Process for Gas Turbine Rotor Straightening

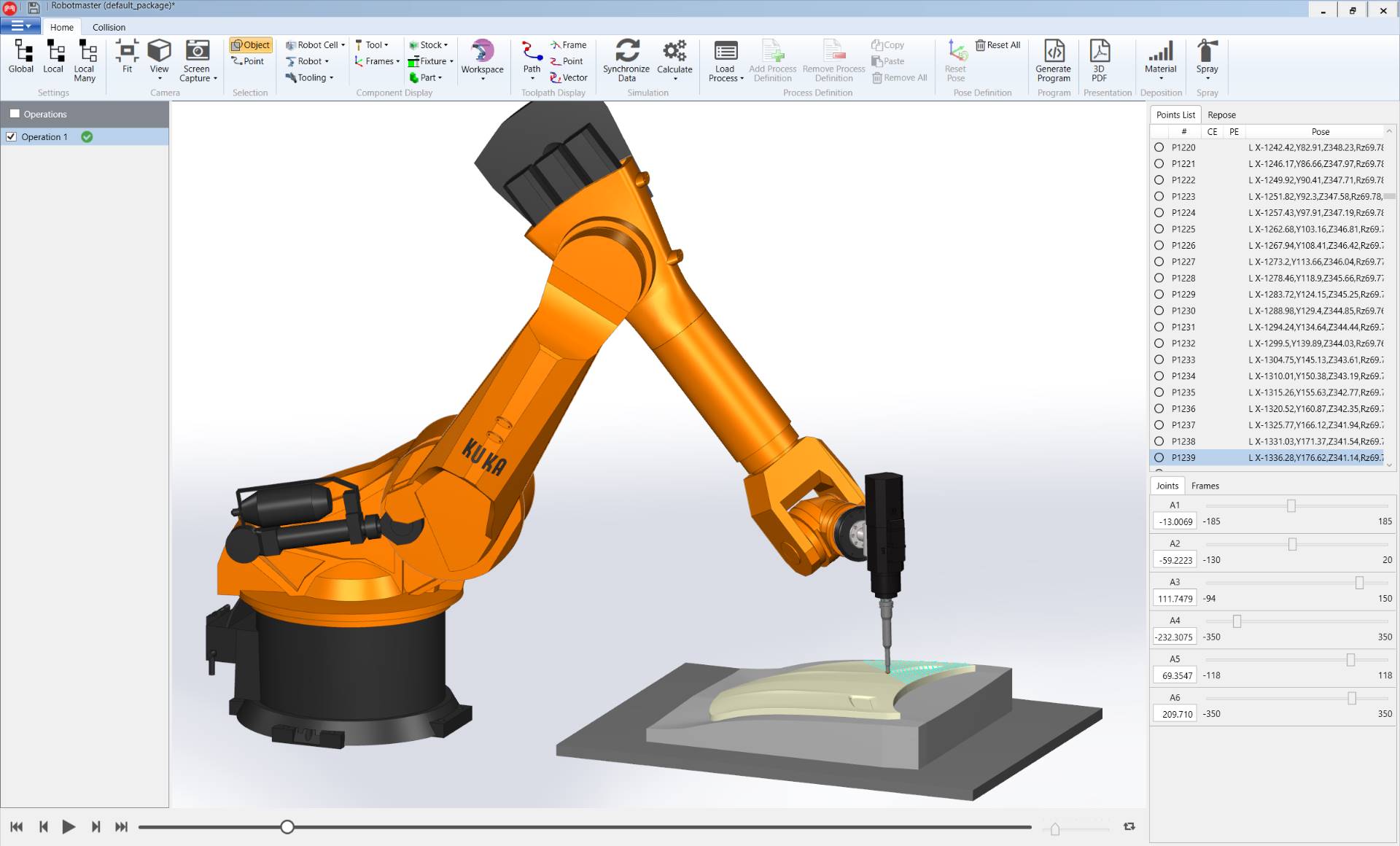

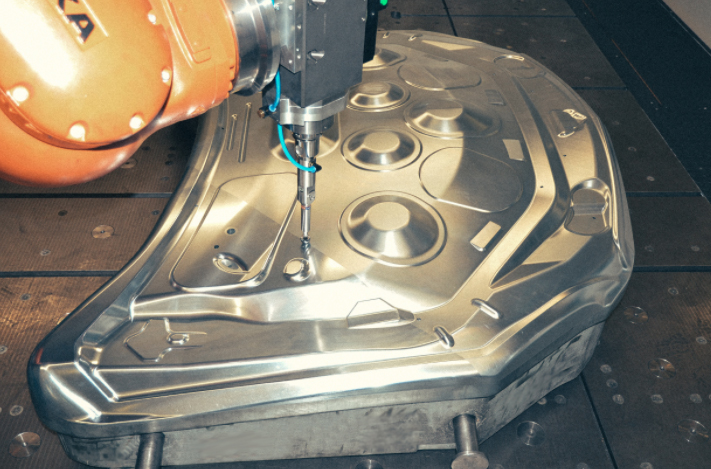

Offline Programming Software is Single Solution for Robotic Hammer Peening of Automotive Stamping Dies | ManufacturingTomorrow

JMMP | Free Full-Text | Surface Integrity of AISI 52100 Bearing Steel after Robot-Based Machine Hammer Peening

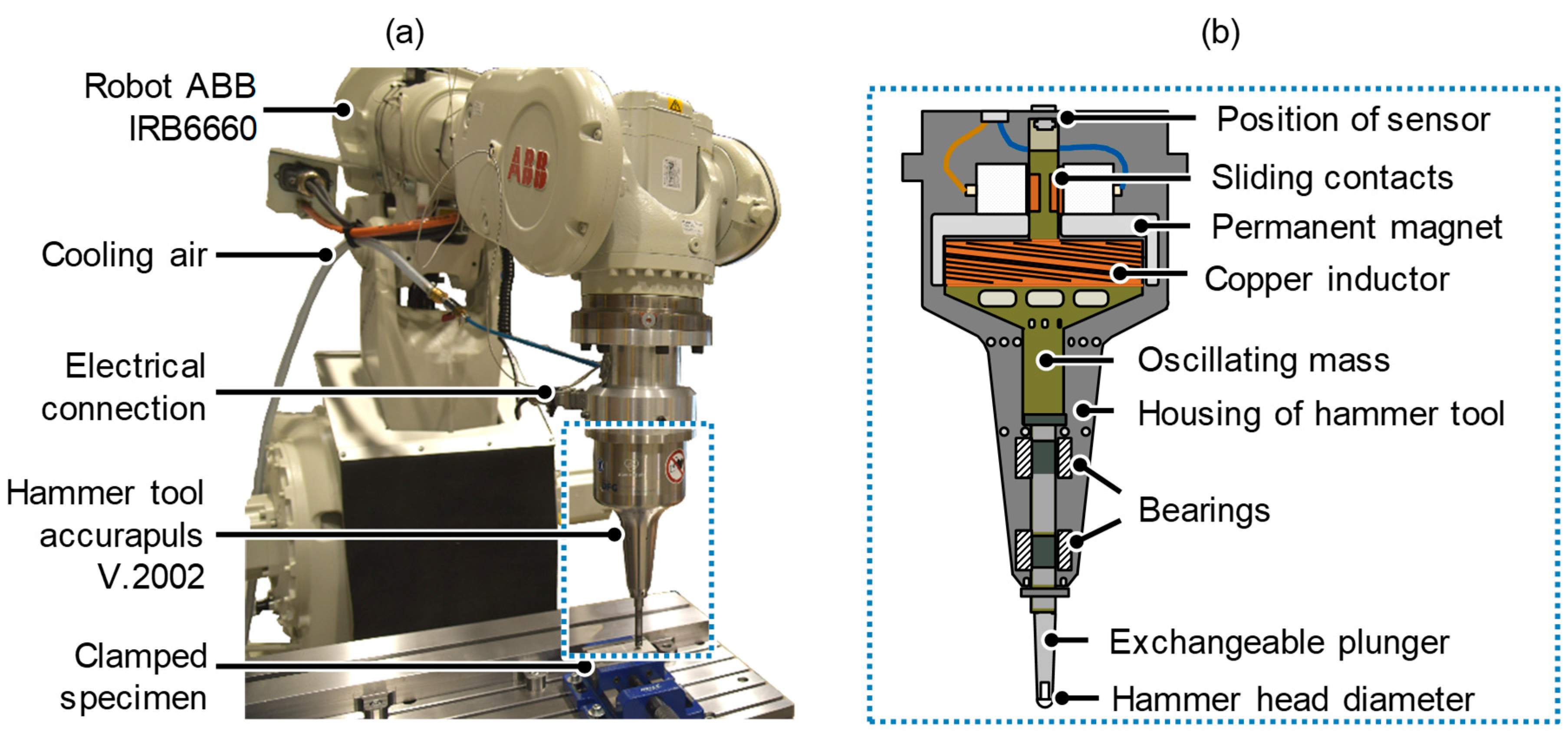

a Setup of mechanical-driven hammer peening tool attaching to robotic... | Download Scientific Diagram

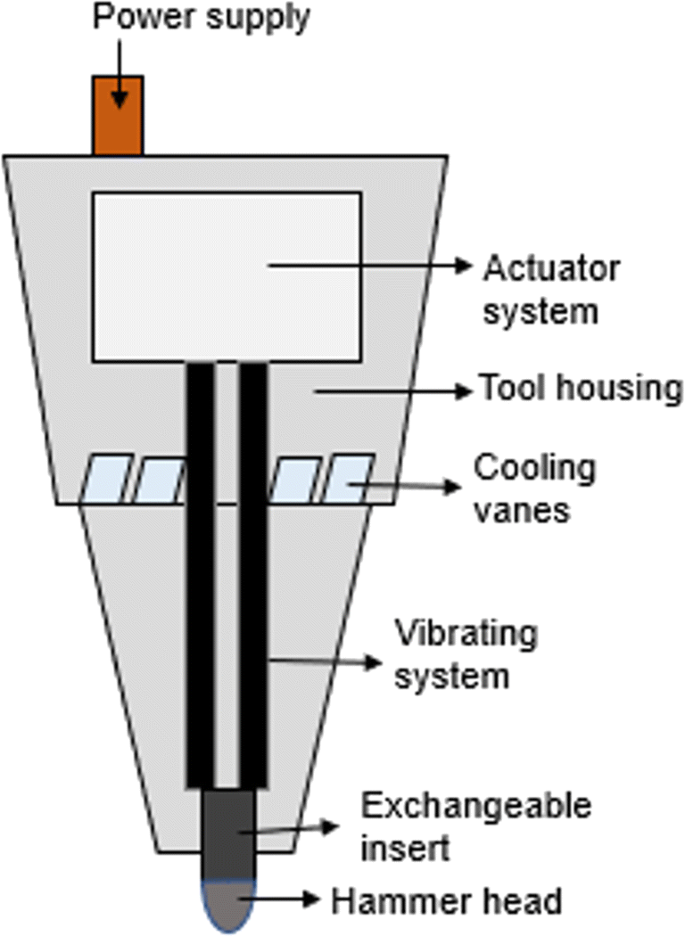

Development of a Multi-physical Kinetics Model for Electrodynamic Machine Hammer Peening Using Machine Learning Approaches | SpringerLink

Microstructure and Mechanical Properties of Wire + Arc Additively Manufactured Mild Steel by Welding with Trailing Hammer Peening - Xiong - 2021 - steel research international - Wiley Online Library